Standard costing versus Dynamic Costing

The main components of traditional standard costing — labor, materials, fixed overhead and variable overhead — only tell part of the story when it comes to determining the true cost of a product. It leaves out several contributing elements that should factor into your business’s actual costs. The standard costing approach may even be damaging a manufacturer’s bottom line by not having a proper understanding of which products are responsible for driving profitability today.

Enable transparency of product cost drivers

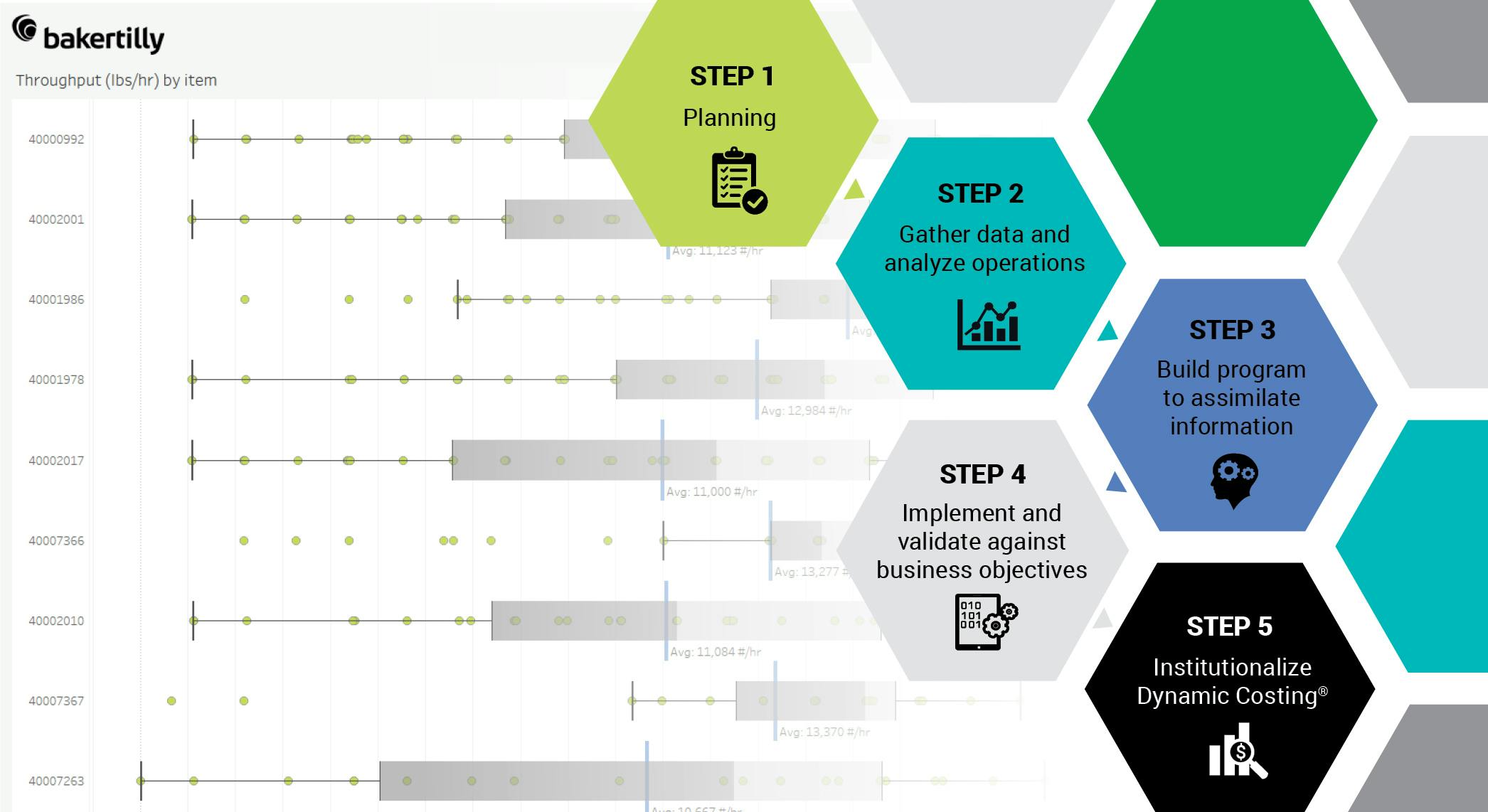

Baker Tilly’s manufacturing analytic and financial services professionals enable transparency of manufacturers’ true product cost drivers with the Dynamic Costing approach. As your organization progresses through its Industry 4.0 journey and goal toward continuous improvement, we leverage Dynamic Costing to reassess your data and provide real-time information to drive business results.

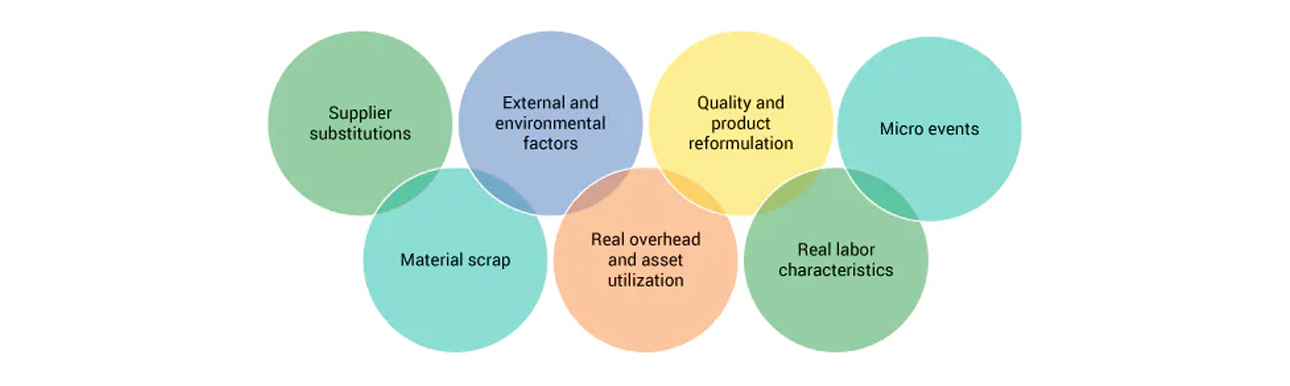

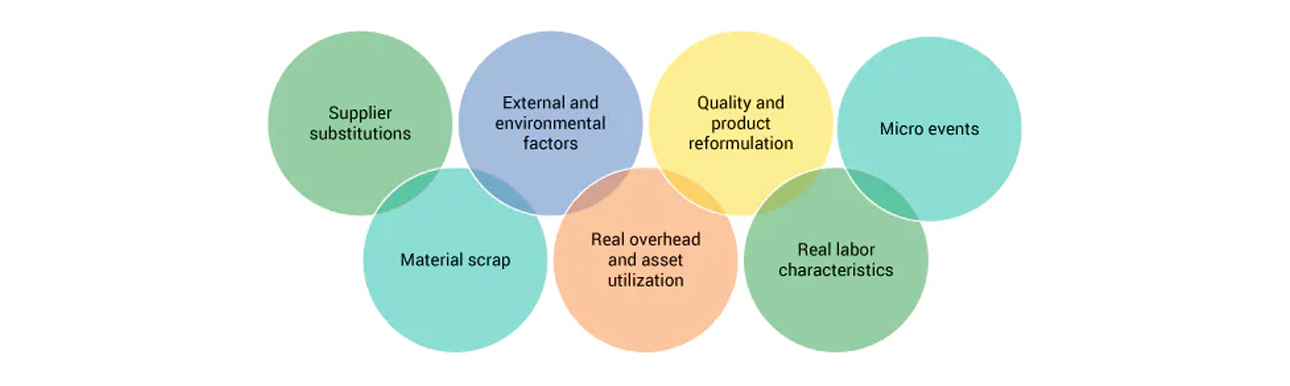

Dynamic Costing measures daily reality: the real individuals and labor that are touching the product. This encompasses material consumption – what’s truly going into the product; real overhead and asset utilization; environmental factors; quality; scrap; and micro events that are tied to assets. All of these tap into integration and automation and try to minimize the manual effort of collecting and managing data to help monitor the business.

To move toward Dynamic Costing, companies will need some tools which are “enablers” of Industry 4.0. Data analytics is one “enabler” that will provide manufacturers with statistically meaningful information. With proper integration, manufacturers can have improved transparency among departments; data accuracy, with reduced errors and time dedicated to manual processes; real-time data gives stakeholders access to critical data in one place whenever they need it; and automation, which eliminates redundancies and increases efficiencies.